Beam Layout Welding Mech4study

Many people assume that H beams or I beams are the exact same. They aren't. While they might share the same structure, purpose and goals, they aren't one in the same. Here are some important differences to remember:

.jpg)

Southern States Machinery has served manufacturers and fabricators since 1995. We are experts in fabrication and machine tools technology. We have an office in North Carolina as well as an office Florida. This gives us the ability to support and sell the most recent fabrication technology.

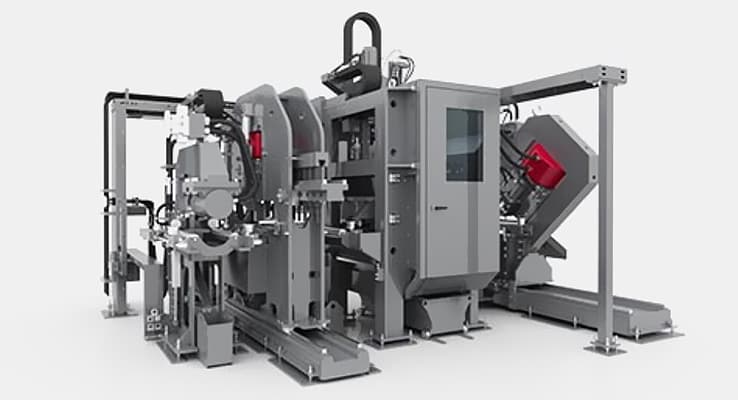

FRANKLIN MODEL PTW72, a complete Automatic submerged dual-arc welding system. It can fixture and weld three-piece, built-up beams that consist of a web and two Flanges. The PTW-72 is capable of a web width of 72 inches and flange capacity of 20 inches wide x 1/4" thick. A PTW72 fabricating unit can reach 300 ft. The system includes a web loading gantry and web seam station. A tack station unit is also included.

Many people assume that H beams or I beams are the exact same. They aren't. While they might share the same structure, purpose and goals, they aren't one in the same. Here are some important differences to remember:

.jpg)

This platform includes rail guards, stairs and a platform. This platform is for flux and wire storage. The operator can load flux hoppers onto the platform and then change wire drums and reels from the platform. Add auxiliary equipment to your Beam Layout Welding machine like the PHI's Beam Turning Device or Flange Titling Device. This will increase speed, agility, and productivity.

While they might look very similar at first glance, you will soon realize that they are quite different once you take into account all the details. Beam layout welding tends to be heavier and denser that I beams. This means that beam layout welding is more capable of absorbing and taking in more force.

Each conveyor section has a load capacity of approximately 4,000 lbs. To minimize friction between the turning roller at the welder entry and the slower-moving beam at its entrance, conveyor speeds are synchronized to welder input speeds.

This wire feeding device can connect wire feeder and reel together using wire feeding pipes. Wire reel supporter can be used to fix wire reel. Before welding, insert wire reel into supporter and then feed wire thrill through feeding tube.

A welded beam consists of three individual sections of steel – a web, a top flange and a bottom flange. These segments are merged together with deep fillet welds to create an incredibly robust building material.